The latest addition to the company’s portfolio of recycling solutions to improve MRF processing and stimulate end markets

AMP Robotics Corp., a pioneer in artificial intelligence (AI), robotics, and infrastructure for the waste and recycling industry, is developing an AI-powered automation solution to improve the recovery of film and flexible packaging. This first-of-its-kind innovation for materials recovery facilities (MRFs) aims to tackle the persistent challenge of film contamination.

A mere 1 per cent of US households have curbside access to recycling film and flexible packaging today estimated by The Recycling Partnership. Yet film and flexibles comprise the fast-growing and second-largest valued packaging segment, behind only corrugated containers and ahead of bottles and another rigid plastic packaging. Close to 95 pounds of these materials, including grocery and storage bags, pouches, and wrappers, are found in the average US home each year.

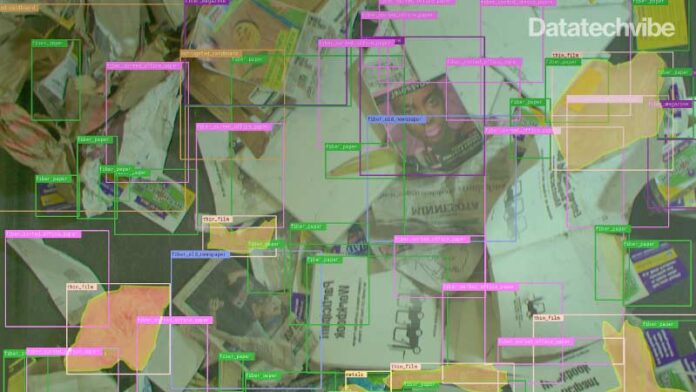

The recycling industry lacks infrastructure for identifying and separating film and flexible packaging, and these materials jam MRF equipment not designed to handle it. Even 2 to 3 per cent of film in overall MRF streams can be unmanageable to remove manually, often damaging equipment, necessitating downtime, and hindering the recovery of recyclables. Film and flexible packaging find their way into every line in an MRF, resulting in high levels of contamination. But most of these materials, given their light weights, make their way onto fibre lines. Film contamination degrades fibre bale purity, leading to revenue loss or the need for additional post-processing downstream.

AMP’s solution, AMP Vortex, is the industry’s first AI-powered automation system for film removal and recovery in MRF environments. AMP’s system targets film contamination and is initially optimised for quality control on fibre lines. Vortex provides the industry with the most flexible and adaptable solution targeting film; it can be deployed as a retrofit solution in various configurations to accommodate different belt sizes and inclines.

“Innovation and infrastructure improvements are vital to helping MRFs process this challenging, prolific material type and increase recycling rates for residential film and flexible packaging,” said Matanya Horowitz, founder and CEO of AMP Robotics. “AI is laying the groundwork to reduce the contamination burden on MRFs and scale the recycling of film and flexible packaging.”

Because these materials are complicated and expensive to reprocess into raw materials, end markets for film and flexible packaging have been limited. While flexible packaging has been almost single-use, major brands continue to make commitments to use more recycled content in their products. Several states have recently adopted laws aimed at ramping up the use of post-consumer resin in plastic products and packaging. AMP is developing Vortex to target and recover film and flexible packaging for baling and selling.

Amanda Marrs, senior director of product for AMP Robotics, added, “With our latest technology innovation for more efficient, profitable recycling operations, we aim to boost recovery and drive demand for products manufactured from recycled film and flexibles to develop and support end markets. This effort is key to addressing the plastic waste crisis and diverting millions of tons of recoverable material from landfills annually.”

Vortex emerged from AMP’s Customer Innovation Program (CIP), a technology program focused on collaborating with industry stakeholders to develop new AI-enabled automation applications for the recycling industry. Vortex is among a portfolio of new products and performance features AMP is developing for pilot and commercial release in support of increased recycling efficiency and improved cost-effectiveness for MRFs and converters.

In alignment with its efforts to economically recover this material type, AMP is a member of The Recycling Partnership’s Film and Flexibles Recycling Coalition, part of The Partnership’s Pathway to Circularity Initiative, a broad group of industry stakeholders seeking to increase curbside collection of film recycling and support end markets for film and flexible products. The Coalition’s primary focus in 2022-2023 is proving efficient and effective collection through pilot projects, infrastructure, and optimisation grants.